Educational Model Ion Thruster

Engineering Project 2018-2019

New Hampshire Science and Engineering Expo

Intro

Engineering Requirements

Engineering Requirements

Engineering Requirements

Create a low-cost spindle frame kit for education applications. Create system for incorporating an ion thruster into the spindle, delivering power, and minimizing rotational friction.

My Role

Engineering Requirements

Engineering Requirements

This was an independent project. I designed, fabricated, tested, and refined all components.

Background

America's education system has few avenues for space-based learning. Because the common core curriculum only includes standards for math, English, and scientific literacy, students often must rely on outside resources - online video, public museums, and mentors - to learn about concepts that spark their curiosity.

I wanted to change this by creating a hands on, interactive, and tactile system that was easy to understand. Putting a kit together that students can use to pursue their passions for science can engage youth in learning. I created a framework designed to be applicable across a variety of thrust systems and used it to investigate the thrust potential of an ion thruster.

Below are initial concept sketches, simplified/ speculative wiring diagrams, and brainstorm documents

Process

The design of the spindle and frame of the device was relatively straightforward. The spindle was laser cut from acrylic and the dimensions were designed to press fit into each other at 90 degree angles.

The most difficult component of the design was the rotational interface between the spindle and frame. These two joints had to retain their conductivity at upwards of 10,000 volts while keeping low rational friction and supporting the full weight of the spindle, ion thruster, accelerometer, and other components. This also meant that if the spindle was not balanced, the joint had to accommodate significant horizontal forces.

A number of joint mechanisms were investigated, some of which are shown below. After much trial and error and, unfortunately, custom part modifications full continuity and smooth rotation were achieved.

Final Outcomes

Due to the voltage and current applied, the thrust output appeared to be minimal. Even with such a low friction retention system as the panel divot system, the thruster was unable to rotate the spindle. However, a teaching device that satisfied most all design requirements was created at a low cost.

Below is the initial test video as well as other detailed media

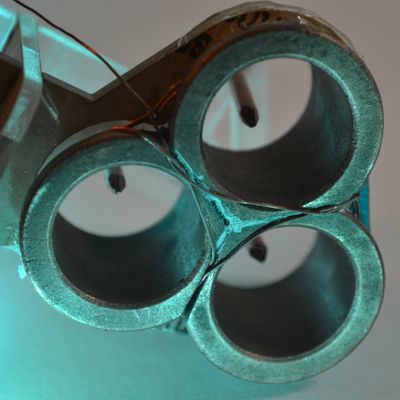

Close up of thruster. Wire wraps around three copper tubes which are welded at the center.

Media Gallery

A video of the first ever test. Thruster is mounted in plastic frame and wooden frame holds thruster tubes.

The complete setup. The frame can be easily compacted, the spindle is free to rotate, and the thruster is balanced with a smartphone. The cabling for high voltage can be seen draped over the spindle.

Awards

This project was awarded first in Physics and Electronics at the New Hampshire Science and Engineering Expo. This project also received a special award, a $2,000 scholarship to the New Hampshire Academy of Science.

Click below to view a copy of the project board

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.